MAKING AND CURING OF CONCRETE CUBES

Hello friends,

In today's post, i will be discussing on how to make and cure a concrete cube.

The standard specified method for making and curing of concrete cube specimen for strength test is found in **BS EN 12390-2. These methods include preparing and filling of the moulds, compacting the concrete using tampin rod, leveling the surface, curing the specimen and transporting them to crushing facility.

Compressive strength of concrete remains one of the most critical properties of concrete that should be tested in construction, this is because it is linked to the load bearing capacity of the concrete and it's durability.

Procedures

- Concrete cube specimens are cast in a steel or iron moulds of 150 x 150 x 150 mm cubic shape.

- It is essential that the mould should have rigid connection with the base so as to prevent leakage of cement mortar during compaction.

- The cube is filled in 3 layers with fresh concrete and tampped well using compacting rod of 16 mm diameter and 16 cm long.

- Each layer is compacted with 35 blows and the tamping should penetrate the previous layer while compacting the subsequent layer.

- At the end of the compaction, the surface is made to flush with the edges of the mould using a trowel.

- The mould is covered immediately with wet hessian cloth and left for 24hrs under a temperature of 22 - 32 °c

- The cubes are marked with an identification number when slightly hardened.

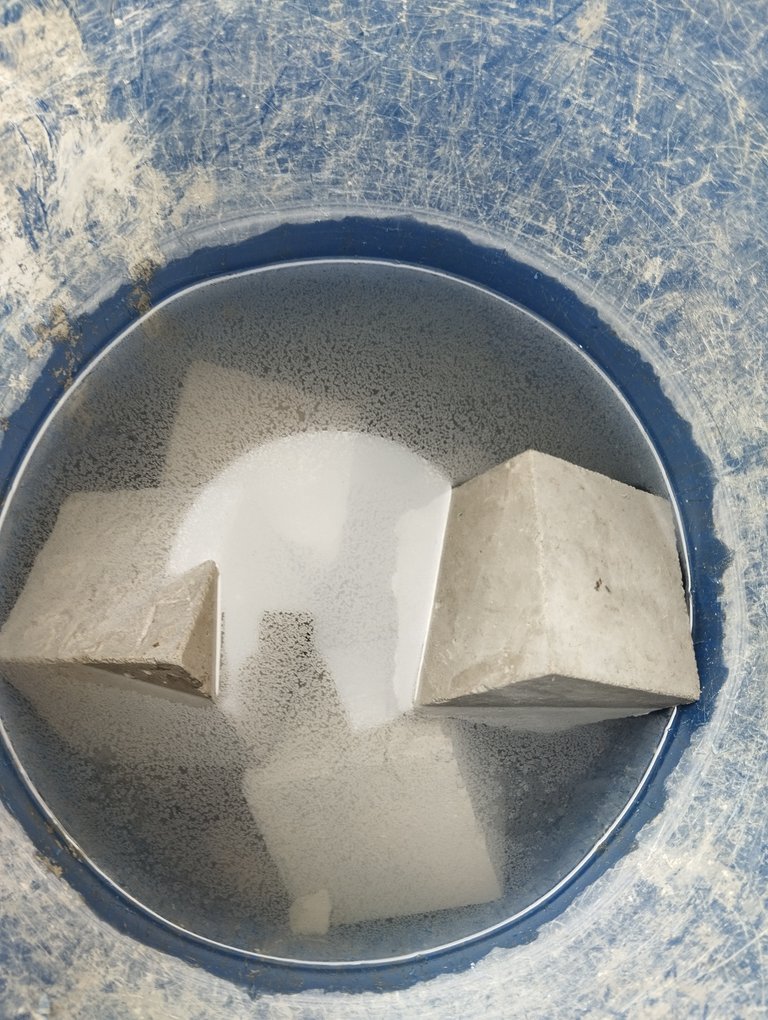

- After 24hrs, the mold is striped off and the cubes are submerged in water for curing.

- The cured cubes are taken out of water and tested in the compression testing machine after 28 days